Introduction

Solar panels, also known as photovoltaic (PV) panels, are devices designed to convert sunlight directly into electrical energy. They are central to renewable energy systems, particularly within efforts toward sustainability, reducing dependence on fossil fuels, and mitigating climate change. As global energy demand surges, understanding how solar panels function, their composition, and their applications becomes increasingly critical.

The solar energy industry has witnessed rapid growth, driven by technological advancements, declining costs, and supportive policies. Solar panels are now commonplace on residential rooftops, large commercial buildings, and even expansive solar farms.

Contents:

Basic Principles of Solar Panels

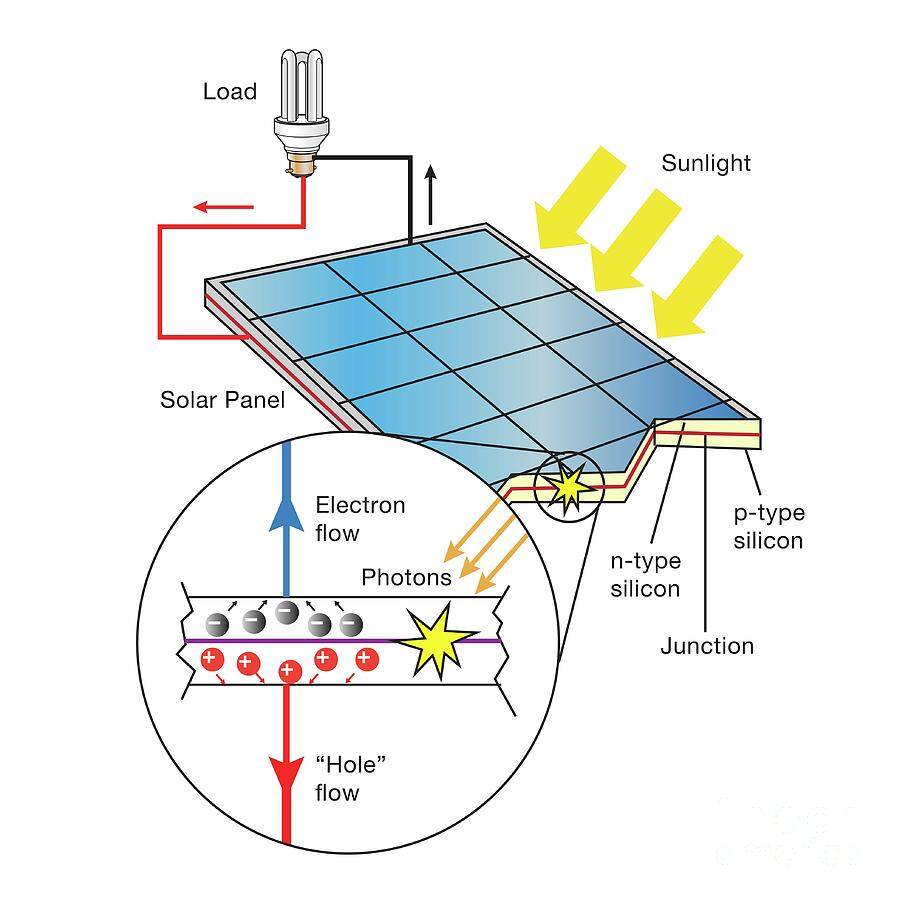

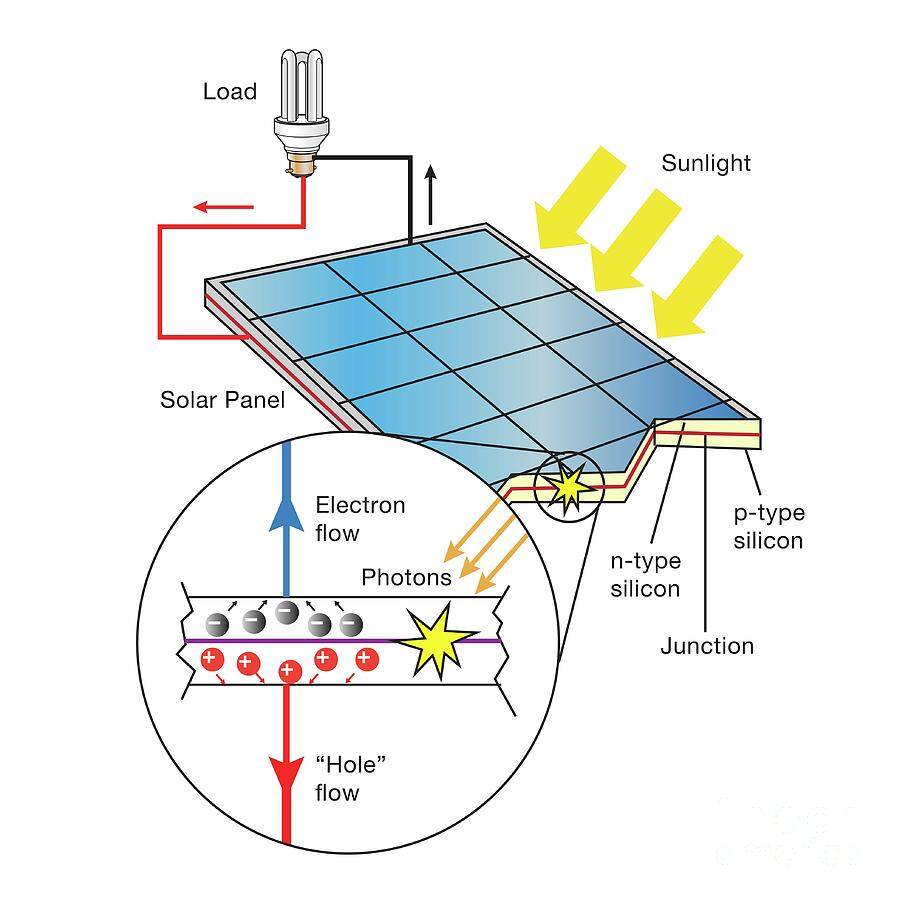

Photovoltaic Effect

At the core of solar panel functionality is the photovoltaic effect, first observed in 1839 by French physicist Edmond Becquerel. When photons from sunlight strike a semiconductor material, electrons are excited, generating an electric current. This direct conversion of solar radiation into electricity is the foundation of solar energy systems.

Semiconductor Materials and Energy Conversion

Most solar cells are made from silicon, a widely abundant semiconductor material. Silicon is favored for its suitable electronic properties, stability, and abundance. Silicon wafers are treated chemically and physically to optimize electron flow and minimize energy loss.

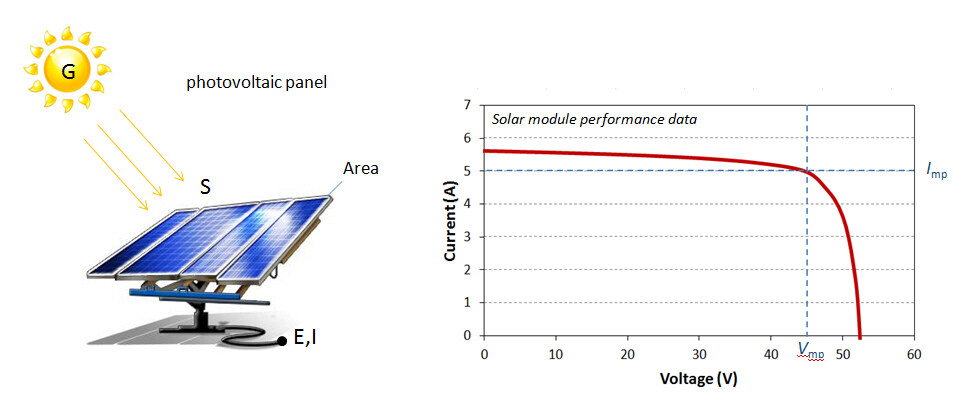

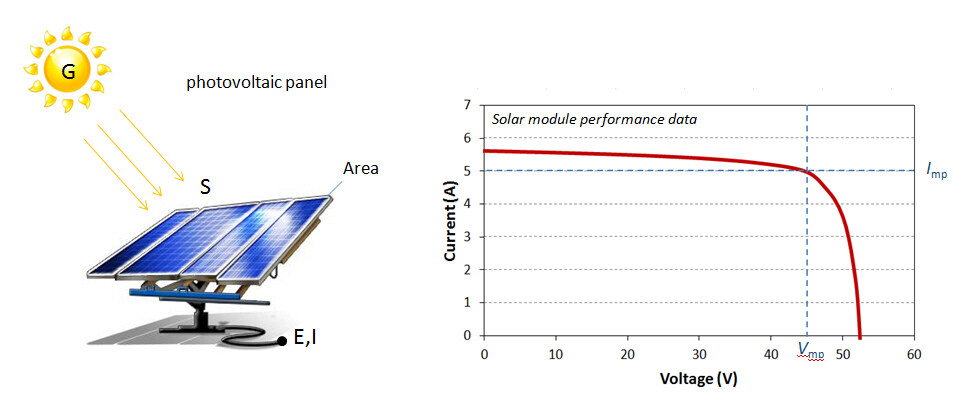

Photovoltaic module operation and its current-voltage (I-V) performance characteristics.

Conversion Efficiency

The efficiency of solar panels, defined as the proportion of sunlight converted into usable electricity, is influenced by multiple factors, including material quality, temperature, and cell design. Efficiency rates for commercial panels typically range from 15% to 22%, while specialized panels, such as those used in space applications, may achieve over 30%.

Structure and Composition of Solar Panels

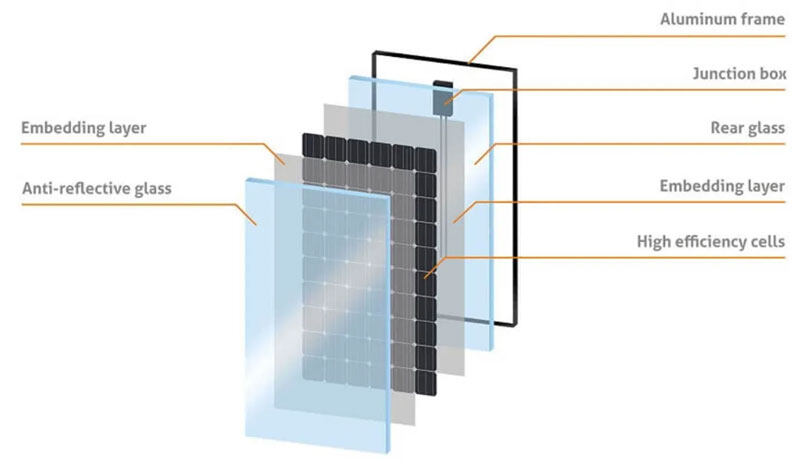

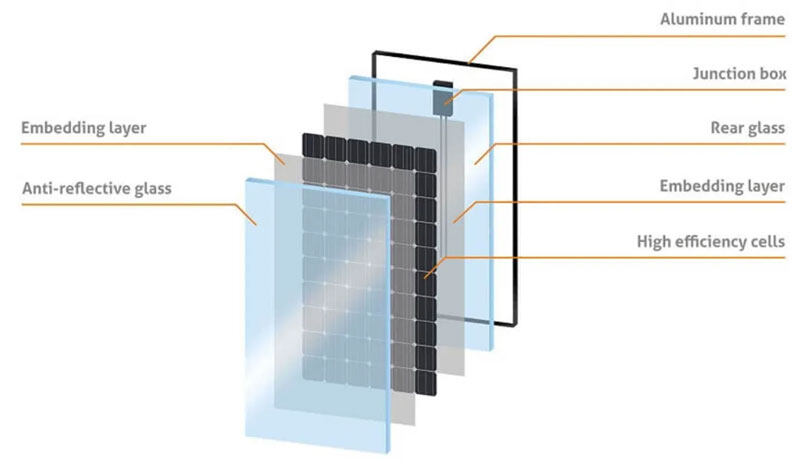

Solar Cells

Solar panels are composed primarily of interconnected solar cells. Each solar cell acts as a basic building block, typically generating about 0.5 volts. Cells are arranged in series and parallel configurations to achieve the desired voltage and current levels.

Encapsulation Materials

Solar cells are encapsulated between layers of ethylene vinyl acetate (EVA), a polymer providing durability and protection. A tempered glass layer covers the front surface, protecting the cells from environmental impacts while allowing maximum solar transmission.

Frames and Backing

Aluminum frames surround solar panels, providing structural integrity, ease of installation, and grounding. Panels have a backsheet typically composed of weather-resistant materials, further protecting internal components.

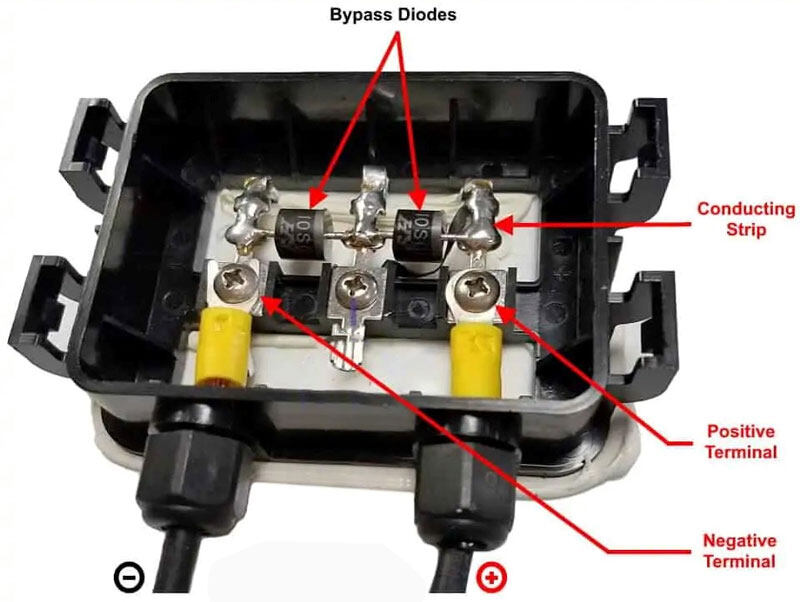

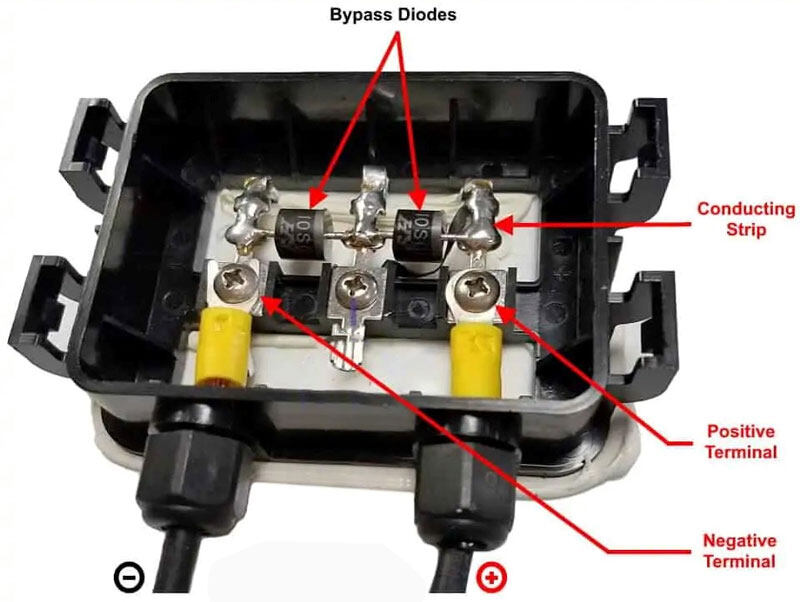

Junction Boxes and Wiring

The junction box on a solar panel's rear side safely houses electrical connections, incorporating bypass diodes to prevent overheating. Durable cables enable electrical transmission from panels to inverters or storage systems.

Types of Solar Panels

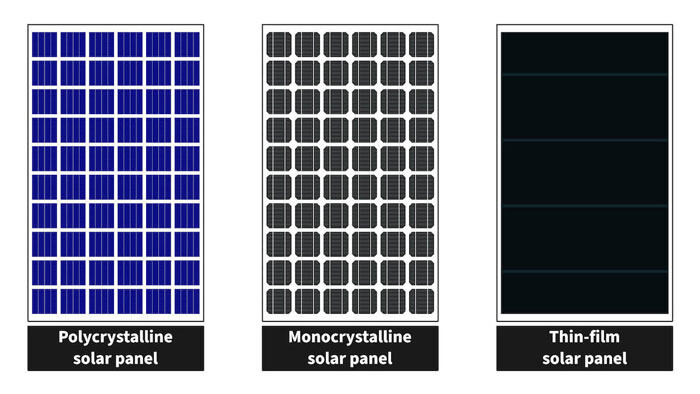

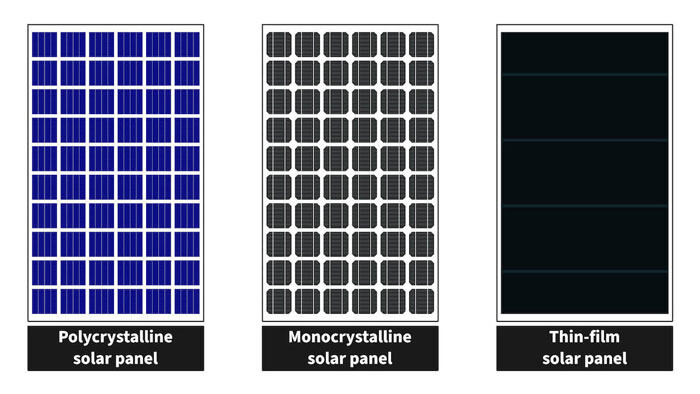

Monocrystalline Solar Panels

Monocrystalline panels are made from single-crystal silicon cells, identifiable by their uniform dark appearance and rounded cell edges. These panels boast higher efficiencies, typically between 18% and 22%, and require less space, making them ideal for residential and space-constrained installations.

Polycrystalline Solar Panels

Manufactured from multiple silicon fragments melted together, polycrystalline panels appear bluish and have visible grain boundaries. Though slightly less efficient (around 15% to 18%), they offer cost advantages and a balanced performance, suitable for large-scale solar installations.

Thin-Film Solar Panels

Thin-film panels are created by depositing semiconductor layers onto substrates like glass, plastic, or metal. Common materials include cadmium telluride (CdTe), amorphous silicon, and copper indium gallium selenide (CIGS). While less efficient (10%-12%) and requiring more surface area, thin-film panels are cheaper, flexible, and suitable for various applications.

Manufacturing and Production Process

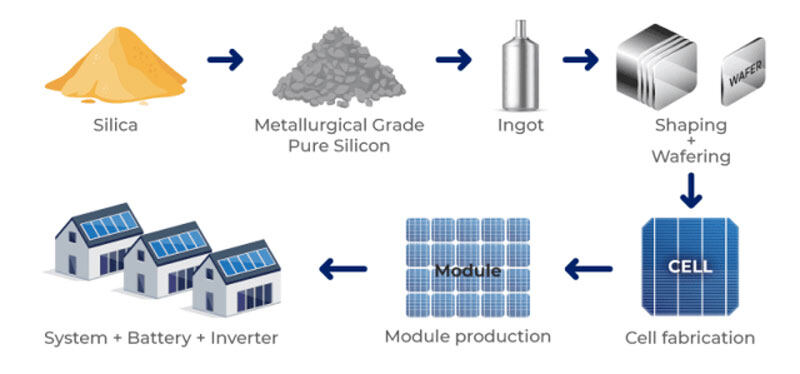

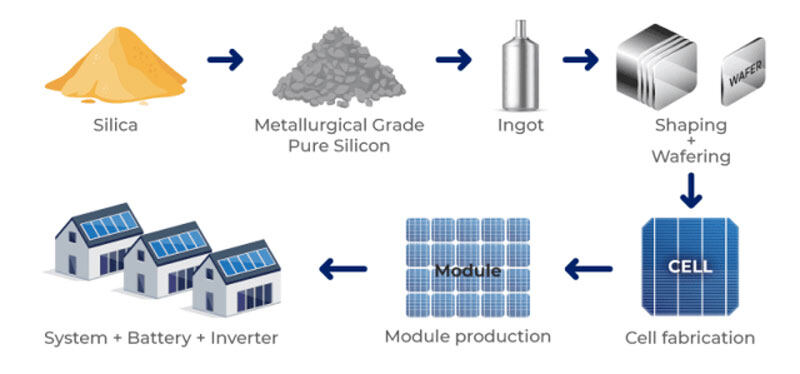

Raw Material Extraction and Purification

Silicon extraction begins with silica sand, which undergoes high-temperature processes to achieve metallurgical-grade silicon. Further refinement results in solar-grade silicon with significantly higher purity, essential for efficient photovoltaic operation.

Wafer Production

Purified silicon is cast into ingots, then sliced into thin wafers using specialized cutting equipment. The precision and thickness of wafers impact the efficiency, quality, and overall cost-effectiveness of solar cells.

Cell Manufacturing and Assembly

Solar cells undergo multiple treatments, including doping (adding phosphorus or boron) to create semiconductor properties, applying anti-reflective coatings to enhance light absorption, and screen-printing conductive gridlines for current collection. These cells are then electrically interconnected, encapsulated, and framed into panels.

Quality Control and Testing

Quality assurance involves comprehensive electrical performance testing, including efficiency checks, durability assessments, and environmental stress tests, ensuring compliance with industry standards and certifications like IEC and UL.

Applications and Practical Examples

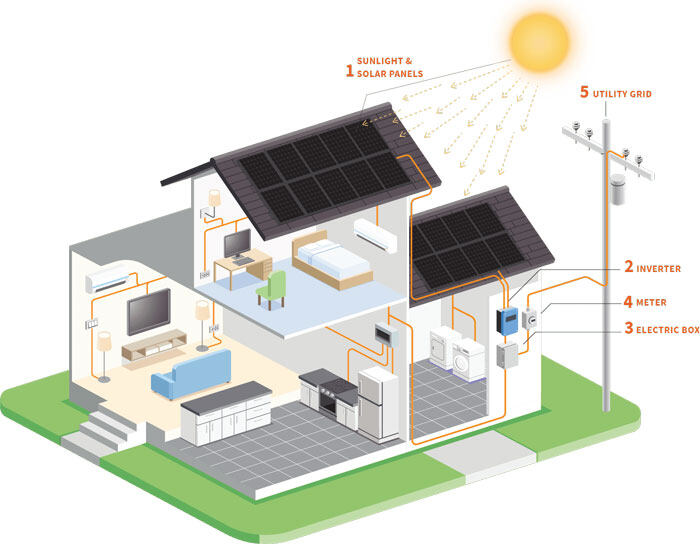

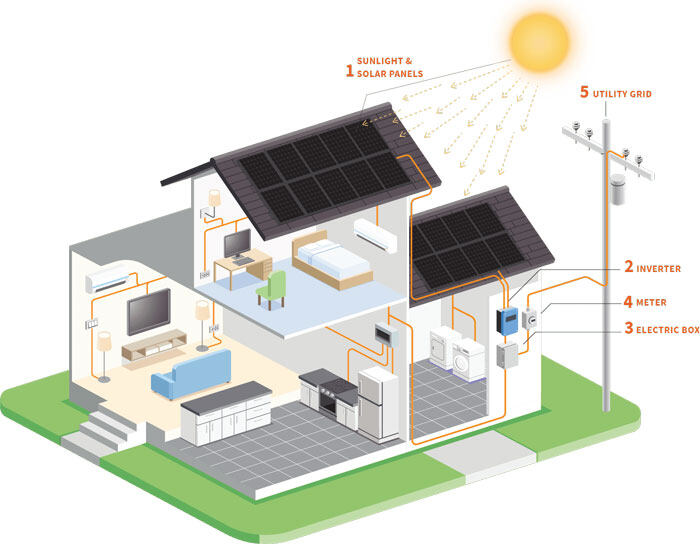

Residential Solar Systems

Solar panels installed on rooftops offer households renewable energy solutions, reducing dependence on grid electricity and providing long-term savings. Residential setups often incorporate energy storage systems for maximizing energy utilization and independence.

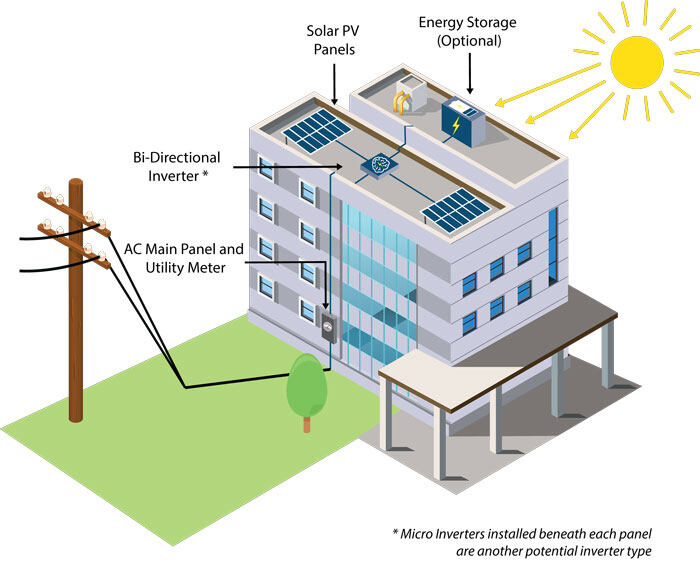

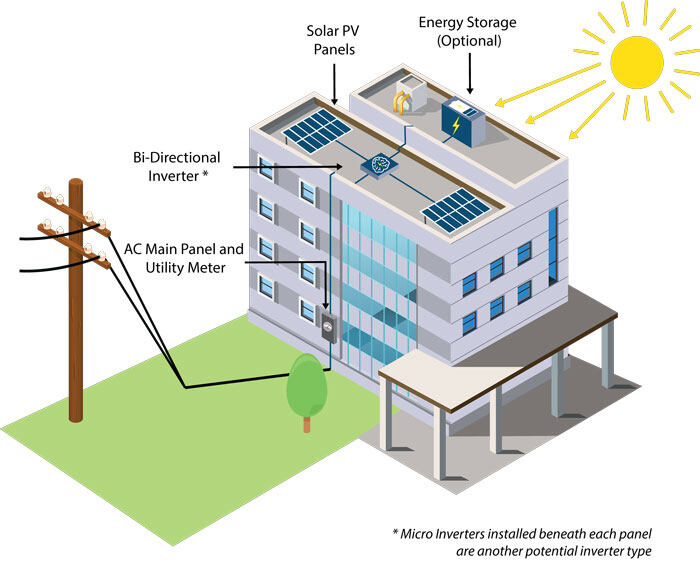

Commercial and Industrial Installations

Large-scale commercial solar installations, frequently seen atop warehouses, factories, and office buildings, significantly offset operational energy costs and carbon footprints. Industrial solar farms, deploying thousands of panels, contribute massively to national energy grids.

Agricultural and Remote Areas

Solar panels are instrumental in powering remote agricultural operations, including irrigation systems, electric fencing, and off-grid rural electrification. Solar pumps and portable systems have improved productivity and access to reliable energy in underserved regions.

Hybrid and Integrated Systems

Integration of solar panels with streetlights, electric vehicle charging stations, and smart-grid systems highlights the adaptability and scalability of solar technology. This synergy supports broader renewable energy transitions across urban and rural environments.

Advantages and Disadvantages of Solar Panels

Advantages

-

Renewable and Sustainable: Unlimited and clean energy source.

-

Economic Benefits: Reduction in electricity bills and potential income generation via feed-in tariffs.

-

Environmental Impact: Minimal emissions and a significantly smaller carbon footprint compared to fossil fuels.

-

Technological Accessibility: Easy installation, maintenance, and increasingly affordable technology.

Disadvantages

-

Initial Cost: High upfront investment can be a barrier.

-

Efficiency Limitations: Dependency on weather conditions and geographic location limits consistent performance.

-

Space Requirements: Solar energy systems require adequate space for effective energy production.

-

Waste and Recycling Issues: End-of-life management remains challenging due to complex recycling processes.

Maintenance and Lifecycle Management

Routine Maintenance

Solar panel maintenance primarily involves regular cleaning and visual inspections to remove debris, dirt, and shading objects. Maintenance ensures optimal efficiency and extends panel lifespan, typically over 25 to 30 years.

Double-head fully automatic, convenient and efficient cleaning

Performance Monitoring and Troubleshooting

Real-time monitoring systems track energy production, promptly identifying performance issues. Technological advancements in monitoring and IoT integration allow quick diagnosis, reducing downtime and enhancing overall system reliability.

Recycling and Disposal

Effective recycling methods for solar panels are essential to address environmental concerns and resource recovery. Emerging recycling technologies aim to recover valuable materials like silicon, silver, and aluminum, significantly reducing waste streams and enhancing sustainability.

FAQs

How long do solar panels typically last?

Most solar panels have a lifespan of 25 to 30 years. While their energy output gradually declines over time, many panels continue to function well beyond this period at slightly reduced efficiency. Quality, maintenance, and environmental conditions can influence longevity.

Do solar panels work on cloudy or rainy days?

Yes, solar panels still work during cloudy or rainy conditions, though their energy production drops to about 10%–25% of peak capacity depending on cloud density. They operate best under direct sunlight but can still generate power in diffused light.

What’s the difference between on-grid and off-grid solar systems?

On-grid systems are connected to the utility grid and allow excess energy to be sent back (often for credit).

Off-grid systems operate independently using battery storage and are ideal for remote locations without access to the power grid.

How is the efficiency of a solar panel measured?

Efficiency is the percentage of sunlight converted into usable electricity. It’s calculated by dividing the panel’s electrical output by the amount of solar energy it receives. Higher efficiency panels require less space for the same power output, which is important for rooftop systems.

Are solar panels environmentally friendly to produce and dispose of?

While solar panels are eco-friendly during operation, manufacturing involves energy use and some hazardous materials. However, the environmental footprint is far lower than fossil fuels. Recycling initiatives are improving, aiming to recover up to 90% of valuable materials like silicon, glass, and metals.