As the global shift toward renewable energy accelerates, homeowners, businesses, and large-scale developers are increasingly turning to solar power. However, selecting the right type of solar panel for your needs in 2025 involves more than just looking at price or aesthetics. Two of the most common solar technologies today are monocrystalline (mono) and thin-film solar panels, each offering distinct advantages and trade-offs.

In this article, we’ll compare monocrystalline and thin-film solar panels across various categories including efficiency, durability, installation, aesthetics, cost, and ideal use cases, to help you decide which technology is best suited for your project in 2025.

What Are Monocrystalline and Thin-Film Solar Panels?

Monocrystalline Solar Panels

Monocrystalline panels are made from a single crystal structure of silicon. The silicon wafers are cut from cylindrical ingots and are known for their high efficiency, long lifespan, and premium appearance—typically with a uniform dark black color.

Thin-Film Solar Panels

Thin-film solar panels are created by depositing one or more layers of photovoltaic materials (like cadmium telluride, amorphous silicon, or CIGS) onto a substrate such as glass, plastic, or metal. They are flexible, lightweight, and usually less expensive to produce, but often come with lower efficiency ratings.

1. Efficiency

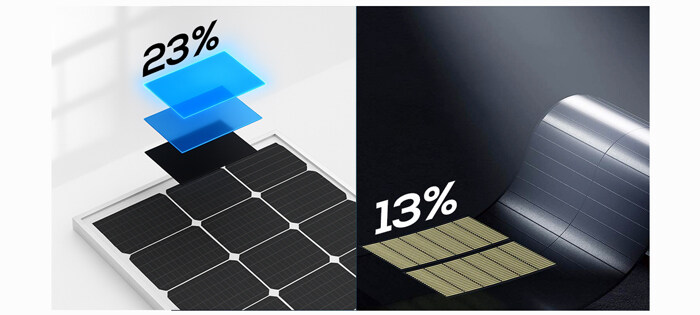

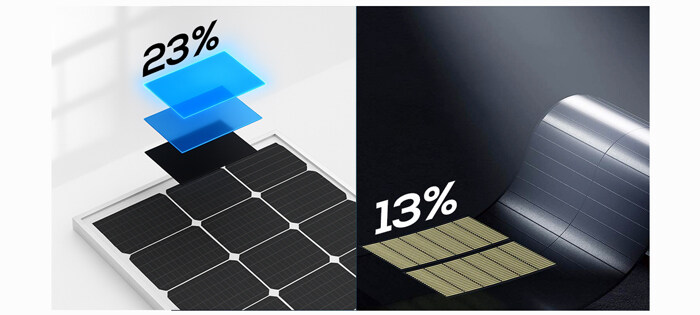

| Type |

Average Efficiency (2025) |

Range |

| Monocrystalline |

20% – 23% |

Up to 24% |

| Thin-Film |

10% – 13% |

Up to 15% (CIGS) |

Monocrystalline panels are the clear winners when it comes to energy conversion efficiency. In 2025, the best monocrystalline modules can exceed 23%, thanks to advances like passivated emitter rear cell (PERC) technology and heterojunction cells. Thin-film panels lag behind, though some advanced types (like CIGS) have narrowed the gap slightly.

Winner: Monocrystalline

2. Space Efficiency

If roof space or land area is limited, higher-efficiency monocrystalline panels are generally preferred. They generate more power per square meter, making them ideal for urban rooftops or small properties. Thin-film panels, due to their lower efficiency, require significantly more surface area to produce the same amount of energy.

Winner: Monocrystalline

3. Cost and ROI

| Type |

Cost per Watt (USD, 2025) |

ROI Timeframe |

| Monocrystalline |

$0.30 – $0.45 |

6–9 years |

| Thin-Film |

$0.20 – $0.30 |

7–12 years |

Thin-film panels are generally cheaper to manufacture and install. They are a good fit for large-scale installations where space is abundant and initial cost is a priority. However, because monocrystalline panels are more efficient and durable, they often deliver a faster return on investment, particularly in residential and commercial projects.

Winner: Depends on project size and budget

4. Durability and Lifespan

| Type |

Lifespan |

Degradation Rate |

| Monocrystalline |

25–30 years |

~0.3–0.5%/year |

| Thin-Film |

10–20 years |

~1%/year |

Monocrystalline panels are built to last. Their rigid structure and robust encapsulation allow them to withstand extreme weather conditions, from hail to high temperatures. Thin-film panels are more susceptible to degradation over time and may not hold up as well in harsh environments.

Winner: Monocrystalline

5. Weight and Flexibility

Thin-film panels are extremely lightweight and flexible, making them ideal for surfaces where traditional panels cannot be installed—such as curved rooftops, carports, RVs, and portable solar solutions. Monocrystalline panels are heavy, rigid, and require sturdy mounting systems.

Winner: Thin-Film

6. Installation and Maintenance

Thin-film panels are easier to transport and install, especially in large utility-scale installations or unique architectural designs. Their flexible nature allows for faster deployment with minimal structural support. Monocrystalline panels, while more complex to install due to weight and rigidity, require less surface area and fewer panels overall.

In terms of maintenance, monocrystalline panels often require less frequent upkeep, while thin-film panels might degrade faster if not well maintained.

Winner: Tie, depending on project conditions

7. Aesthetic Considerations

Monocrystalline panels are sleek and uniform in appearance, often with black frames and cells. They are generally considered more attractive, especially for modern residential installations. Thin-film panels have a matte finish and can be semi-transparent or integrated into building materials like windows or facades, offering more design flexibility.

Winner: Subjective — Monocrystalline for sleekness, Thin-Film for integration

8. Environmental Impact

Thin-film panels, particularly those made from cadmium telluride, raise concerns over the use of toxic materials. However, their production can be less energy-intensive than monocrystalline panels. Monocrystalline silicon requires significant energy during manufacturing, but recycling programs for silicon-based panels are more developed and safer.

Winner: Depends on material and end-of-life recycling

9. Ideal Use Cases in 2025

| Use Case |

Best Option |

| Urban Rooftops |

Monocrystalline |

| Off-grid Mobile Systems |

Thin-Film |

| Commercial Rooftops |

Monocrystalline |

| Building-Integrated PV (BIPV) |

Thin-Film |

| Utility-Scale Solar Farms |

Thin-Film (cost) |

| Extreme Weather Environments |

Monocrystalline |

Making the Right Choice in 2025

Choose Monocrystalline if you:

-

Have limited roof or land space.

-

Want maximum efficiency and long-term performance.

-

Prioritize aesthetics for residential or commercial use.

-

Need durability in extreme climates.

Choose Thin-Film if you:

-

Need lightweight, flexible solar for mobile or portable applications.

-

Have a large installation area and want lower initial costs.

-

Plan to integrate solar into building materials (like glass or facades).

-

Are working on utility-scale or remote projects where panel weight and ease of installation are crucial.

The Bottom Line

In 2025, monocrystalline panels remain the go-to solution for most residential and commercial solar energy systems thanks to their superior efficiency, longevity, and proven technology. Thin-film panels, while not as efficient, offer unique advantages for large-scale, mobile, or integrated applications where flexibility and low weight matter most.

Ultimately, your choice should align with the specific demands of your project—be it maximizing energy output in a small space or deploying lightweight panels across large surfaces. Consulting a solar professional can help determine which panel type best fits your performance, budget, and environmental goals.