Energy storage has emerged as a pivotal technology in shaping the future of power management and sustainability. Particularly significant in this sphere are commercial and industrial energy storage systems, which are designed specifically to accommodate the unique power needs, cost structures, and operational dynamics of commercial and industrial sectors respectively. Although they share some similarities, crucial distinctions exist between commercial and industrial energy storage systems in terms of capacity, application, functionality, and economics. Understanding these differences is essential for effective system design, deployment, and optimization.

Defining Commercial Energy Storage

Commercial energy storage systems are tailored primarily to meet the needs of businesses such as retail stores, office buildings, hotels, and restaurants. These establishments typically require energy solutions capable of providing reliable power supply, reducing energy costs, managing peak demand charges, and ensuring compliance with sustainability standards.

Commercial systems are typically smaller-scale and optimized to balance the variability of daily operations. They help mitigate peak electricity demand by storing energy when it is cheap—often during off-peak hours—and releasing it during peak periods, thus ensuring stable and cost-effective electricity usage.

Commercial storage systems frequently employ battery technologies such as lithium-ion due to their flexibility, modularity, compact size, high efficiency, and declining costs. Additionally, their smaller footprint allows easy integration into densely populated urban environments or limited-space facilities.

Defining Industrial Energy Storage

In contrast, industrial energy storage systems are specifically engineered to support large-scale manufacturing facilities, factories, processing plants, mining operations, and heavy industrial complexes. These facilities have significantly larger and more intensive power demands and require robust solutions capable of handling substantial energy fluctuations, power outages, voltage stabilization, and extensive peak shaving.

Industrial energy storage systems are typically larger, more complex, and equipped to deliver greater power output and storage capacity. Their operational demand necessitates the use of more advanced or heavy-duty technologies, including flow batteries, large-scale lithium-ion battery arrays, and compressed air or pumped hydro storage systems.

The main objective of industrial storage solutions is not merely to reduce costs, but also to provide reliability, efficiency, and resiliency in power supply—often critical to maintaining uninterrupted operations, reducing downtime risks, and enhancing industrial productivity.

Key Differences in Scale and Capacity

The scale and capacity of energy storage systems highlight one of the most fundamental differences between commercial and industrial storage. Commercial systems often range in capacity from several kilowatt-hours (kWh) to a few hundred kilowatt-hours, sufficient to cater to the energy needs of medium-sized commercial operations.

Industrial systems, however, commonly range from hundreds of kilowatt-hours to multiple megawatt-hours (MWh). These systems are designed to handle significantly greater energy demands and power fluctuations, accommodating intensive industrial processes such as manufacturing lines, heavy machinery operations, and continuous production cycles.

Variations in Application and Functionality

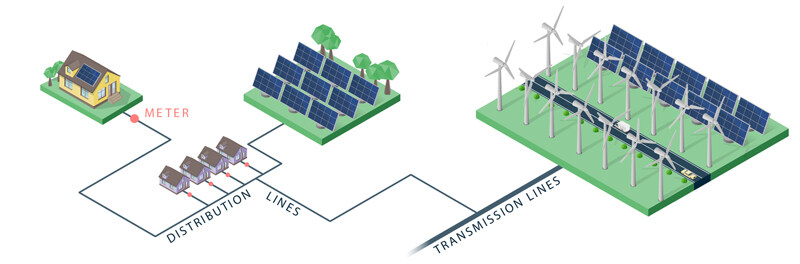

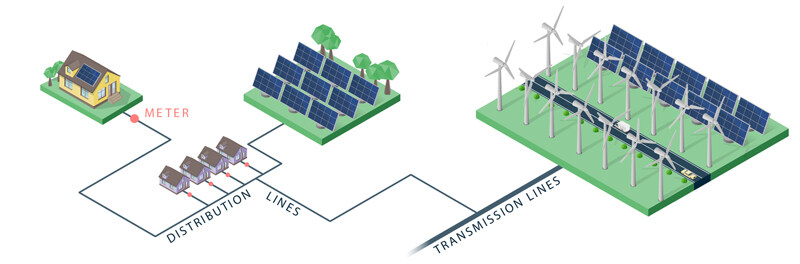

Commercial storage applications primarily focus on optimizing energy usage patterns, lowering electricity costs, enhancing power quality, and meeting sustainability targets through renewable integration, such as solar or wind. Typical functionalities include demand charge management, load shifting, frequency regulation, and backup power during outages.

In contrast, industrial energy storage applications are more multifaceted and demanding. These systems often have the additional tasks of stabilizing grid interactions, facilitating peak shaving during high energy consumption processes, supporting microgrids, managing significant power outages, and enabling extensive renewable integration to support sustainability commitments at scale.

Furthermore, industrial storage often includes more advanced management systems, such as sophisticated supervisory control and data acquisition (SCADA) platforms, tailored for detailed monitoring, extensive analytics, and precise control of large-scale operations.

Economic Considerations and Return on Investment

Economic considerations differ significantly between commercial and industrial energy storage systems. For commercial applications, cost-effectiveness is largely driven by reductions in electricity bills, particularly from peak demand charges, and potential incentives or subsidies related to renewable energy usage or emissions reductions. The financial return typically involves shorter payback periods, influenced by relatively modest upfront investment and manageable operational costs.

Industrial energy storage investments, however, often involve substantial upfront costs due to their size, complexity, and infrastructure requirements. The financial justification in industrial settings is typically supported by extensive cost savings from reduced downtime, improved operational efficiency, decreased reliance on grid-based power during peak tariff periods, and substantial environmental compliance savings. Industrial projects generally have longer-term horizons and thus require careful evaluation of total lifecycle costs and comprehensive financial planning.

Integration with Renewable Energy

Another critical area where differences between commercial and industrial energy storage manifest distinctly is in renewable energy integration. Commercial facilities often integrate energy storage primarily to supplement renewable energy sources like rooftop solar installations. Here, storage supports self-consumption, enabling better utilization of generated renewable energy and minimizing dependence on grid-supplied power.

Industrial facilities, given their larger operational scales, tend to integrate renewable energy sources on a significantly grander scale, involving wind farms, large solar arrays, or biomass power generation. Storage systems in these environments are critical in handling intermittent renewable generation, smoothing out fluctuations, and guaranteeing consistent energy availability even when renewable inputs diminish.

Regulatory and Environmental Implications

Regulatory environments for commercial and industrial energy storage also differ considerably. Commercial storage systems are typically easier to deploy, facing less stringent regulatory scrutiny due to their smaller size and local-scale implications. Commercial installations usually benefit from straightforward permitting processes and localized incentives.

Industrial energy storage installations, due to their significant scale and impact, typically face more stringent regulations and longer permitting timelines. These systems often must comply with detailed environmental impact assessments, stringent safety standards, rigorous grid interconnection requirements, and substantial regulatory oversight.

Conclusion

Commercial and industrial energy storage systems, while overlapping in certain technological and operational aspects, differ substantially in their scale, applications, economics, and regulatory landscapes. Commercial systems cater to smaller-scale, more flexible power needs primarily aimed at cost optimization and renewable integration. Industrial systems, conversely, offer higher capacities, advanced functionalities, and address more critical reliability and operational efficiency concerns. Clearly understanding these differences is essential for stakeholders aiming to optimize their energy storage deployments effectively and sustainably in the evolving energy landscape.