Solar panels are essentially glass-covered semiconductor devices that perform best when their surface is clean and unobstructed. Even a thin layer of dust or organic film can reduce energy output by several percent, and heavier soiling—such as bird droppings or industrial soot—can create localized hot spots and accelerate degradation.

As more residential, commercial, and utility-scale systems are deployed, panel owners are discovering that the cleaning tool itself is a critical part of system performance. The wrong brush can:

-

Scratch anti-reflective (AR) coatings

-

Leave streaks or sticky residue

-

Fail to remove baked-on contaminants

-

Increase the risk of microcracks through excessive pressure

By contrast, a purpose-designed solar panel cleaning brush maintains high transmittance, protects coatings, and reduces cleaning time per square meter. Before looking at specific brush types, it helps to understand what you are actually cleaning off the glass.

|

Contaminant Type

|

Main Source

|

Adhesion Level

|

Typical Impact on Yield

|

Recommended Cleaning Approach

|

|

Light Dust

|

Wind-blown soil, dry roads

|

Low

|

1–5% loss over time

|

Soft brush or microfiber with low-pressure water

|

|

Pollen

|

Seasonal plant and tree bloom

|

Medium

|

Up to 5–10% during peak season

|

Microfiber or soft-bristle brush with ample rinse

|

|

Bird Droppings

|

Bird nesting and roosting

|

High

|

Local hot spots and severe shading

|

Targeted soaking plus soft-bristle brush, no harsh scraping

|

|

Industrial Soot

|

Factories, highways, diesel exhaust

|

Medium–High

|

5–15% if not cleaned regularly

|

Water-fed brush with purified water and controlled agitation

|

|

Salt Spray

|

Coastal or marine environments

|

Medium

|

Corrosion risk and gradual yield loss

|

Regular rinse with soft brush and fresh water

|

Types of Solar Panel Cleaning Brushes

In 2026, the market for solar cleaning equipment ranges from simple manual tools to specialized water-fed and motorized systems. Understanding the main categories helps you narrow down options early:

-

Manual brushes (telescopic handle)

Extendable poles made from aluminum or carbon fiber allow safe cleaning from the ground or from a secure walkway, reducing the need for ladders or roof walking.

-

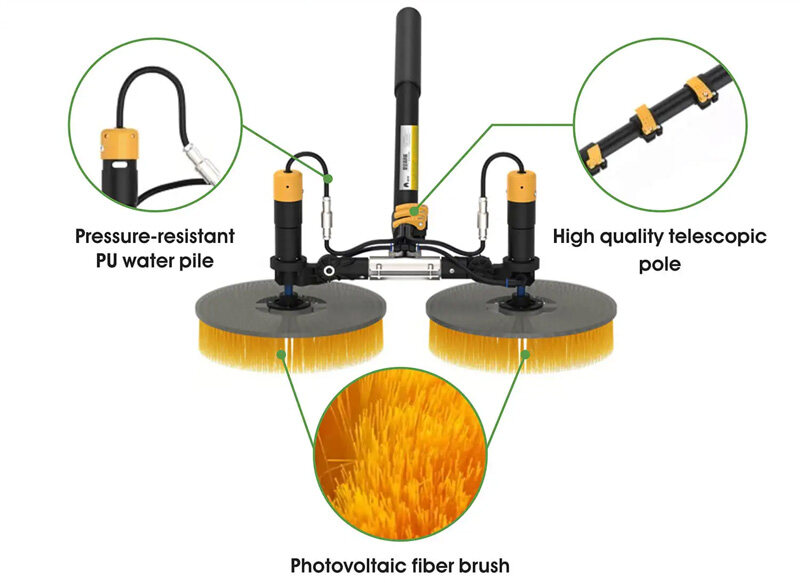

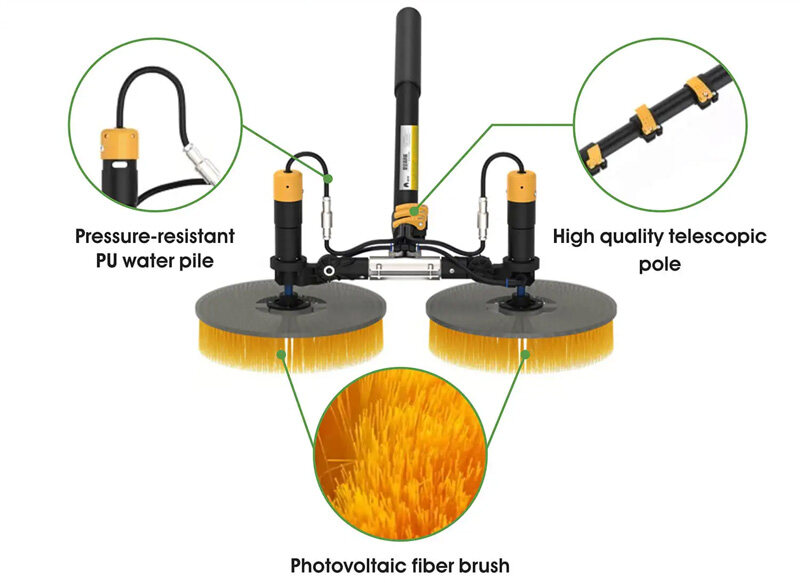

Water-fed brushes and flow-through systems

Brushes connected to a hose or pump system that deliver water directly through the brush head. Often combined with DI or RO water to avoid mineral spotting.

-

Soft-bristle, microfiber, and silicone-edge brushes

These refer to the contact material on the panel surface. Microfiber and silicone edges are typically used for low-scratch, high-safety applications, while soft nylon bristles are preferred for more stubborn soiling.

Choosing among these types depends on system size, access, safety constraints, and local soiling conditions.

Key Features That Define a High-Quality Brush

Not all “solar brushes” are created equal. A high-quality cleaning brush is defined by a combination of material properties, ergonomics, and hydraulic design.

Bristle and cleaning material softness

The contact surface should be softer than the glass coating and free of sharp edges. Fine microfiber or carefully rounded nylon bristles minimize micro-abrasions, which can otherwise accumulate and scatter light.

Brush width and coverage area

A wider brush covers more panel area per pass, improving productivity. However, excessive width can make the brush hard to maneuver and increase weight at the pole tip.

Telescopic pole length and material

For rooftop systems, poles must be long enough to reach upper rows from a safe position. Carbon fiber poles are lighter and stiffer than aluminum, reducing operator fatigue and flex.

Water delivery mechanism

Flow-through designs reduce the need to manage a separate hose and help flush debris away from the glass. Compatibility with deionized or reverse-osmosis water is important in hard-water regions to avoid spotting.

Weight and ergonomics

Extended cleaning sessions on large arrays require low tool weight, comfortable grips, and balanced pole design. A slightly higher purchase price often pays off in lower labor fatigue.

Replaceable heads and maintenance

Professional brushes use screw-on or quick-connect heads so worn bristles or pads can be replaced without discarding the pole assembly. This lowers long-term cost and keeps performance consistent.

|

Material

|

Scratch Risk

|

Water Retention

|

Durability

|

Best Use Case

|

Notes

|

|

Microfiber Pad

|

Very Low

|

High

|

Medium

|

Residential rooftops, coated glass

|

Excellent for fine dust and pollen with minimal abrasion

|

|

Soft Nylon Bristles

|

Low

|

Medium

|

High

|

Industrial dust and heavier soiling

|

Effective on stubborn deposits when used with gentle pressure

|

|

Silicone Edge

|

Very Low

|

Low

|

High

|

Quick maintenance passes, water squeegeeing

|

Pushes debris and water efficiently without scratching

|

|

Natural Fiber

|

Medium

|

Medium

|

Medium

|

Budget tools, small off-grid systems

|

Higher friction; not ideal for sensitive AR coatings

|

Compatibility and Safety Considerations

A cleaning tool must be compatible not just with the glass but with the full module construction and installation environment.

Compatibility with different panel coatings

Many modules now incorporate hydrophobic or self-cleaning coatings. Aggressive or abrasive materials can strip these layers. Always confirm the panel manufacturer’s cleaning guidance and choose brush materials that comply.

Pressure limitations and microcrack risk

Modules are designed to withstand snow and wind loads, but point loads from poles or boots can still induce microcracks. The brush should distribute pressure over a wide area, and operators should avoid leaning body weight onto the glass.

Slip, fall, and electrical safety

For rooftop arrays, the safest brush is one that allows cleaning from a stable platform—ideally the ground or a guarded walkway. Poles should be non-conductive or properly insulated, especially around live DC wiring and combiner boxes.

Hot vs. cold surfaces

Cleaning extremely hot modules with cold water can introduce thermal stress. Whenever possible, clean early in the morning or on overcast days when module temperature is closer to ambient.

Cleaning agents and purified water

Most manufacturers recommend deionized or softened water and neutral pH cleaners only when necessary. Strong detergents, ammonia, or abrasive powders can etch glass or leave films that attract more dirt.

Performance Testing and Evaluation Criteria

For professional buyers and O&M service providers, the best solar panel cleaning brush is the one that passes structured, repeatable tests.

Cleaning efficiency in one pass

A good brush should remove the majority of dust and organic film in one or two passes. Additional passes reduce productivity and increase labor cost.

Water consumption and flow rate

Water-fed systems should balance adequate rinsing with reasonable water use, measured in liters per square meter. High-efficiency brushes reduce both time and water per cleaned module.

Time required per square meter

The combination of brush width, ergonomics, and cleaning efficiency drives the number of square meters cleaned per hour—critical for large C&I or utility-scale projects.

Anti-scratch laboratory testing

High-end tools are often tested on coated glass samples using standardized abrasion tests, checking for changes in transmittance or surface roughness after many cleaning cycles.

Durability and environmental resistance

Brushes used outdoors must withstand UV exposure, temperature swings, and, in some locations, salt mist. Bristle fatigue and pole wear should be evaluated over hundreds of hours of use.

Cleaning Efficiency vs. Number of Passes

Different brush types might perform across repeated passes on a moderately soiled panel.

In a real test, you would replace the sample values with measured “before and after” transmittance or normalized power output.

How to Choose the Right Brush

1. Match Brush Type to Soiling Conditions

Different contaminants require different cleaning materials and brush aggressiveness:

-

Light dust / pollen → microfiber or ultra-soft bristle brush

-

Bird droppings / sticky residue → soft nylon bristle with adequate soaking

-

Industrial soot / heavy particulates → water-fed or rotary brush with higher agitation

-

Coastal salt spray → frequent rinsing with soft, water-fed brushes

Proper matching minimizes abrasion while ensuring efficient cleaning.

2. Consider System Size and Accessibility

-

Small residential rooftop: lightweight telescopic pole, microfiber brush

-

Medium commercial rooftops: wide brush head for higher productivity

-

Large C&I or utility arrays: motorized rotary brushes or professional water-fed systems

System size directly impacts the needed brush width, pole length, and ergonomics.

3. Determine Cleaning Frequency

Your cleaning schedule depends heavily on local climate and pollution:

-

Dry, dusty, or agricultural regions: monthly or bi-monthly

-

Urban traffic or industrial zones: frequent cleaning during peak pollution cycles

-

Humid climates with frequent rain: quarterly may be sufficient

Choose tools durable enough for your expected cleaning frequency.

4. Balance Budget and Professional Requirements

-

Homeowners can prioritize affordability and ease of use.

-

Technicians and O&M providers benefit from carbon-fiber poles, wide heads, and long-lifespan brushes that reduce labor hours.

High-end tools often deliver better total cost of ownership for large systems.

5. Evaluate Compatibility and Essential Accessories

Ensure the brush and pole system supports:

Accessories often determine final cleaning quality and overall convenience.

FAQs

Do different mounting configurations (tilted vs. flat roofs) require different brush types? +

Yes. Flat-roof systems accumulate significantly more dust and water pooling, often requiring wider brushes or water-fed systems to flush away debris efficiently. Tilted roof installations typically collect less standing residue, making lightweight microfiber or telescopic brushes more effective. Flat roofs also benefit from slightly higher agitation tools because gravity does not assist debris removal.

Is purified water always necessary when cleaning with a high-quality solar brush? +

Not always. Purified (DI/RO) water is essential in regions with hard water to prevent mineral spotting and streaks, especially on high-transmittance AR coatings. In areas with naturally soft water, a soft-bristle brush and adequate rinsing are usually sufficient. For commercial O&M operations, purified water is preferred because it ensures consistent results across diverse environmental conditions.

How does brush weight influence cleaning performance and operator fatigue? +

Brush weight directly affects maneuverability and the operator’s endurance—especially when using long poles. Heavier brush heads increase pole flex and reduce precision, which can lead to uneven pressure on the panel surface. Professional-grade brushes often use carbon fiber poles and lightweight heads to minimize operator fatigue and maintain safe, consistent cleaning pressure.

Are robotic or automated cleaning systems compatible with manual cleaning brushes? +

Yes. Many utility-scale systems use robotic or semi-automated cleaners but still rely on manual brushes for edge cleaning, spot cleaning, or maintenance during robotic downtime. Brushes selected for hybrid cleaning operations should be abrasion-tested and compatible with the panel types used in robotic cleaning zones to avoid inconsistent wear patterns.

Can extreme temperatures affect the performance of cleaning brushes? +

Absolutely. In high heat, bristle materials may soften, reducing cleaning efficiency and increasing drag across the panel surface. In very cold climates, certain plastics and bristles can stiffen or become brittle, raising the risk of micro-abrasions. High-quality brushes in 2026 use temperature-stable polymers or microfiber pads that maintain softness across a wide temperature range.